L&T Group Websites

- Corporate

- Corporate – Arabic

- GreenTech

- Heavy Engineering

- Hydrocarbon

- LTIMindtree

- L&T Construction

- L&T Construction & Mining Machinery

- L&T Finance

- L&T Howden

- L&T Hydraulics

- L&T Infrastructure Development Projects Limited

- L&T Infrastructure Finance Company Limited

- L&T Institute of Project Management

- L&T Technology Services

- L&T Kuwait Construction

- L&T MBDA Missile Systems Limited

- L&T Metro Rail (Hyderabad) Limited

- L&T-MHI Power Boilers

- L&T-MHI Power Turbine Generators

- L&T Realty

- L&T-Sargent & Lundy Limited

- L&T Special Steels and Heavy Forgings

- L&T-SuFin

- L&T Valves Limited

- Nabha Power Limited

- Power

- L&T Public Charitable Trust

- Rubber Processing Machinery

- Shipbuilding

- L&T Skill Trainers Academy

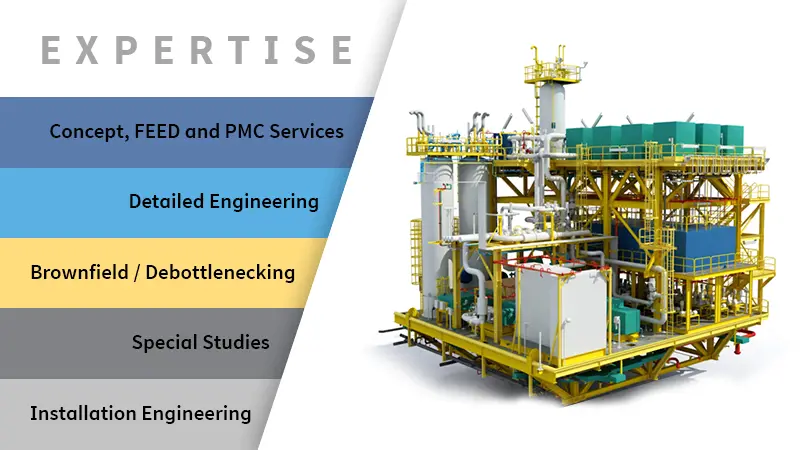

Expertise

We have comprehensive engineering capabilities covering the complete project lifecycle: concept studies, FEED, basic engineering,3D model-based detailed engineering, special studies including safety, risk assessment, brownfield & installation engineering

We have delivered projects worth about 20 million engineering man-hours. Our strong domain expertise has enabled us to engineer some of the biggest and most challenging fast-track projects in the region.

-

Concept, FEED and PMC Services

Our experienced engineers ensure optimised project solutions, with a comprehensive view of engineering, operations, budget, schedule and safety & environment.

Services under this segment include:

- Preparation of Conceptual and Feasibility Study Reports (including CAPEX & OPEX estimates)

- Establishing project design basis, specifications & scope of work

- Special engineering analyses and studies

- Preparation of detailed multi-disciplinary technical bid package for EPIC tenders

- Review and evaluation of EPIC Bids

- Review of Detailed Engineering

- Co-ordination with Third Party Inspection Agency and Classification agency

- Supervision of Factory/Site acceptance Tests

- Construction & Commissioning supervision services

- Progress monitoring and expediting

-

Detailed Engineering

A strong focus on an integrated FEED & Detail Engineering approach helps us achieve optimized layouts, timely procurement of long lead items and accurate material take-offs. Our detail engineering capabilities cover both Greenfield and Brownfield projects for offshore facilities including tie-backs to their corresponding onshore installations.

We believe that Engineering is a vital enabler function for EPC, and optimise the sequencing of engineering deliverables to meet project priorities for procurement, fabrication and installation.

We have integrated best practices with innovation to engineer some very uniquely challenging projects over the years, including India’s largest and most technically challenging process complex, the world’s longest skin-effect heated cross-country pipeline passing through seismic and meandering river zones, India’s only High-Pressure, High-Temperature (HPHT) wellhead facility, a majority of ONGC’s Mumbai High pipeline network, complete FPSO topsides for Brazilian and West African waters, meeting highly demanding project schedules.

-

Brownfield / Debottlenecking

We have experience spanning over 200 revamp engineering projects.

Key benefits:

- Comprehensive, knowledge-backed survey checklists, customised to each asset surveyed

- Use of Laser Scanning and quick turnaround to prepare intelligent models for accurate engineering

- Quick, informed resolution of issues pertaining to constructability, installation, safety and operability

- Optimisation of layouts through site-routing, placement and orientation of field instruments, operation consoles, etc.

- Better alignment of engineering activities with fabrication priorities

-

Special Studies

In addition to routine engineering simulations we also carry out special studies specific to a project’s requirement.

PROCESS

Transient flow analyses

Dynamic simulation

Relief & Blowdown Studies

Radiation & Vent Dispersion study

Survivability analysis

Low temperature metallurgy studies

Adequacy studies for various systems

Flow Assurance Solutions

STRUCTURAL

Finite Element Modelting & Analysis critical joints.

SCFs for topsides joint

Spectral Fatigue

Non-Linear Analysis (USFOS)

- Wave pushover

- Time domain analysis for Rare Intense Earthquake

- Boat Impact

Development of Response Amplitude Operators for Transportation Spectral Fatigue.

Pile Drivability, Sizing and Optimisation.

PIPELINES

Steady State &Transient flow simulation of Single & Multiphase transport pipelines

Sea Bed Interventions / Soil Liquefaction Studies

Floatation Studies Of Buried Pipelines Due To Earthquake & Wave Action

On-bottom Roughness Analysis using SAGE Profile 3D software

Surge Analysis in Pipelines / Networks

Advanced Subsea Pipeline Stability Analysis

On-bottom stability using AGA

NAVAL ARCHITECTURE

Load-out Ballast plan

Sea-fastening

Transportation

Launch

Floatation Upending

On-bottom stability

Barge Stability during Transportation

-

Installation Engineering

We leverage L&T Hydrocarbon Engineering's strong EPC experience to ensure seamless fabrication and installation of facilities designed by us.

Our design covers various aspects of Installation:

- Load-Out and Transportation (including sea fastening and grillage) of Jackets, Decks, Topside Modules

- Launch and Upending of Jackets

- Mooring

- Pipe laying

- Marine Spread

- Craneage and Lifting equipment